-40%

(NEW) RDZ 1/4" CNC 90 DEGREE DIAMOND TIP STAINLESS STEEL DRAG ENGRAVING TOOL

$ 31.67

- Description

- Size Guide

Description

(New and improved diamond tip)We are pleased to say, that our tool supplier and diamond manufacturer have been working together to improve the life of the 90 degree tool. The manufacturer has implemented a new process for our diamonds that will make for a longer lasting tool. The tool are still subject to breakage, but over all will have a longer life and create cleaner results.

RDZ 1/4" DIAMOND DRAG ENGRAVING TOOL WITH 90° TIP

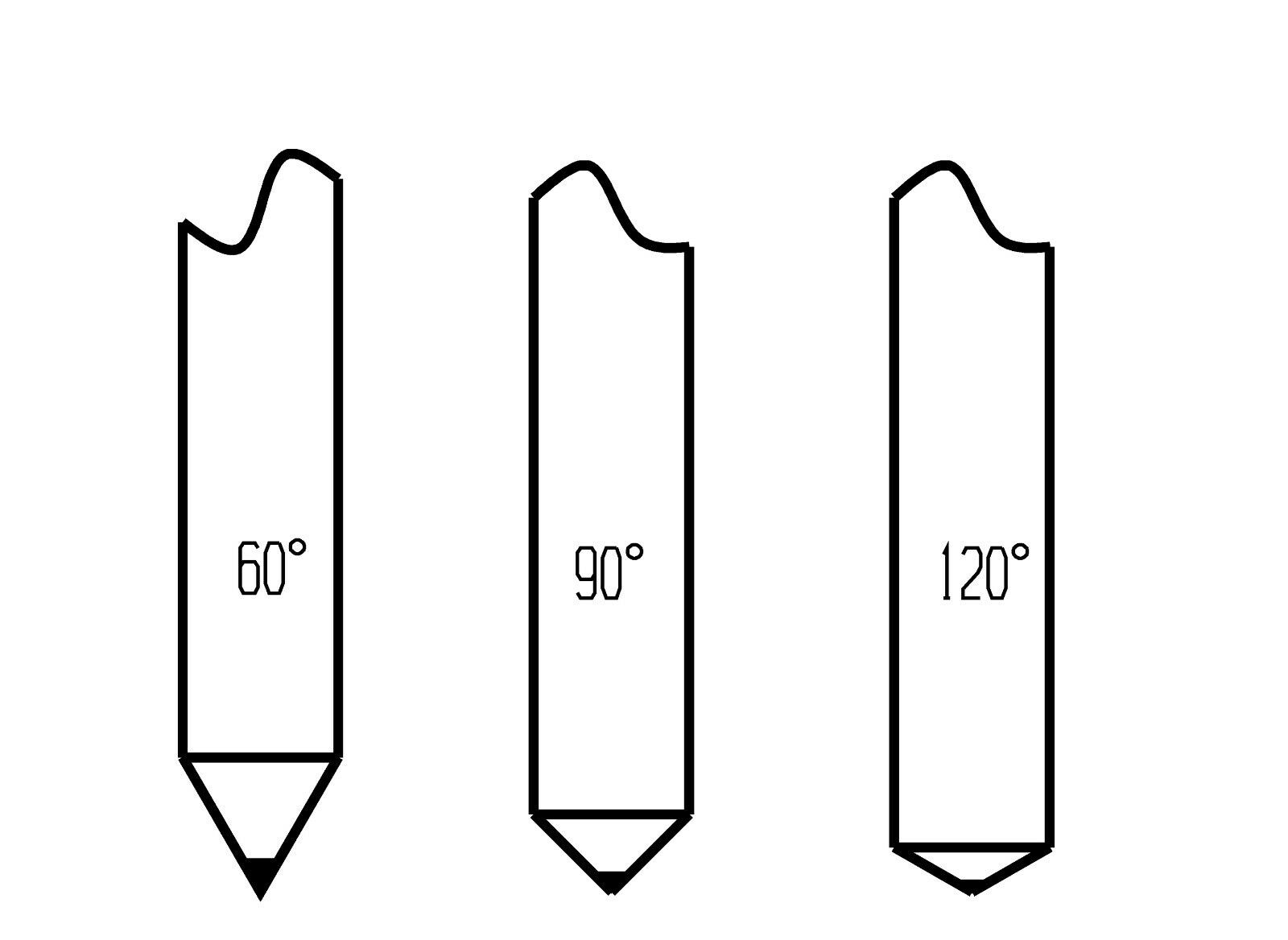

This is a brand new spring loaded drag engraving tool with a 90 degree diamond tip. (See the diagram to show the actual angle of the tool) Many people are confused by what angle you are actually getting. I drew the sketch to help clarify the tool. It can be used on any engraving machine that has a 1/4" collet.

With this type of tool you are able to do very detailed engravings on uneven surfaces and the engraving remains even. The tool does not rotate so you do not need to run the spindle. These are perfect for engraving several types of material including brass, aluminum, glass, fiber board, acrylic, plastic painted surfaces and much more. The tool has a precision ground 1/4" diameter stainless steel body with an 1/8" diamond bit that extends out by approximately 1/2", the overall length is approx. 2" & there is up to 3/8" travel.

These are made in our own machine shop by skilled machinists & each one is inspected and tested before packaging. Don't be fooled by our low price, these are high quality tools made in the USA on CNC machines. If you have any questions please contact us before buying. Thanks for looking and Happy Engraving!

We also have replacement tips available.

Skeleton, Piranha, Laguna, Shark, 3020, 3040, 3060, Taig, Sherline, LXG0609, 2020, 2030, 2040, Oliver, Rising, Konmison, Sanvn, Gtsun, Sungoldpower,

SPARE ENGRAVING BITS

I could easily argue that a spare engraving bit is a must have. Not having a spare engraving bit is like driving a car without a spare tire - if you get a flat, you're in big trouble. Treat the need for a spare engraving bit the same way. If your engraving bit chips or gets dull, you'll be out of business until the manufacturer can get you a replacement. If you just can't afford a spare engraving bit when you purchase your new engraver, make it a goal to get one in as soon as possible. The cost is minimal compared to the down time.

IT IS VERY IMPORTANT TO NOTE, THAT YOU SHOULD NOT RUN THE SPINDLE WHILE YOU ARE ENGRAVING.